5083 Aluminum Coil

Classification :

Aluminum Coil

Key words:

PRODUCT DETAILS

Product Description

5083 aluminum is a non-heat-treatable alloy known for its resistance to extreme environments, including seawater corrosion and industrial chemicals. Although Al-5083 has limited machinability due to its strength, it is a material for marine and aquatic applications and is commonly used in the shipbuilding industry. Other uses for this alloy include transportation applications such as railroads, trucks, and car bodies, as well as pressure vessels and food processors.

Product Parameters

|

Width |

20-3000mm or customized |

Thickness |

0.1-120mm or customized |

|

Length |

100-12000mm or customized |

Certificate |

ISO.SGS.BV |

|

Standard |

He, AiSi, ASTM, GB, DIN, EN etc. |

||

|

Brand |

1000 Series:1050 1060 1070 1100 1200 1235 etc. 3000Series:3003 3004 3005 3104 3105 3A21 etc. 5000 Series:5005 5052 5083 5086 5154 5182 5251 5754 5A05 etc. 6000 Series:6061 6063 6082 6A02 etc. 7000 Series:7050 7475 7075 etc. 8000 Series:8A06 8011 8090 etc. |

||

|

Surface |

Coating, embossing, drawing, polishing, anodizing, etc. |

||

|

OEMService |

Punching, cutting special size, making flat surface, surface treatment, etc. |

||

|

Delivery time |

received.30%After deposit7-15working day |

||

|

Application |

Construction, shipbuilding, decoration, industry, manufacturing, machinery, hardware and other fields |

||

|

Sample |

Free OffersSample |

||

|

Packaging |

Strapping, plastic bag, film, wooden pallet Standard seaworthy export packing or according to customer requirement |

||

chemical composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

- |

0.05 |

0.03 |

0.03 |

- |

99.50 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

0.05 |

0.03 |

0.03 |

- |

99.60 |

|

1070 |

0.20 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

0.04 |

0.03 |

0.05 |

- |

99.70 |

|

1100 |

0.95 Si Fee |

0.05~0.20 |

0.05 |

- |

- |

0.1 |

- |

0.05 |

0.15 |

99.0 |

|

|

2014 |

0.5~1.2 |

0.7 |

3.9~5.0 |

0.4~1.2 |

0.2~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

2017 |

0.2~0.8 |

0.7 |

3.5~4.5 |

0.4~1.0 |

0.4~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

91.5 - 95.5 |

|

2024 |

0.50 |

0.50 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

3003 |

0.60 |

0.70 |

0.05~0.20 |

1.0~1.5 |

- |

- |

0.10 |

- |

0.05 |

0.15 |

Allowance |

|

3A21 |

0.60 |

0.70 |

0.20 |

1.0-1.6 |

0.05 |

- |

0.15 |

0.1-0.2 |

- |

- |

Allowance |

|

3004 |

0.30 |

0.70 |

0.25 |

1.0~1.5 |

0.8~1.3 |

- |

0.25 |

- |

0.05 |

0.15 |

Allowance |

|

3005 |

0.60 |

0.70 |

0.30 |

1.0~1.5 |

0.2~0.6 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Allowance |

|

3105 |

0.60 |

0.70 |

0.30 |

0.3~0.8 |

0.2~0.8 |

0.20 |

0.40 |

0.10 |

0.05 |

0.15 |

Allowance |

|

5005 |

0.30 |

0.70 |

0.20 |

0.20 |

0.5~1.1 |

0.1 |

0.25 |

- |

0.05 |

0.15 |

Allowance |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.2~2.8 |

0.15~0.35 |

0.10 |

- |

0.05 |

0.15 |

Allowance |

|

5754 |

0.40 |

0.40 |

0.10 |

0.50 |

2.6~3.6 |

0.30 |

0.20 |

0.15 |

0.05 |

0.15 |

Allowance |

|

5A05 |

0.50 |

0.50 |

0.10 |

0.3-0.6 |

4.8-5.5 |

- |

0.20 |

- |

0.05 |

0.05 |

Allowance |

|

5083 |

0.40 |

0.40 |

0.10 |

0.4~1.0 |

4.0~4.9 |

0.05~0.25 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

6061 |

0.40~0.8 |

0.70 |

0.15~0.4 |

0.15 |

0.8~1.2 |

0.04~0.35 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

6082 |

0.70~1.3 |

0.50 |

0.10 |

0.4~1.0 |

0.6~1.2 |

0.25 |

0.20 |

0.10 |

0.05 |

0.15 |

Allowance |

|

7075 |

0.40 |

0.50 |

1.2~2.0 |

0.30 |

2.1~2.9 |

0.18~0.28 |

5.1~6.1 |

0.20 |

0.05 |

0.15 |

Allowance |

Mechanical properties

|

Tensile Strength (MPa) |

Yield strength (MPa) |

ElongationRate (%) |

Hardness (HV) |

|

290 |

145 |

22 |

87 |

Physical Performance

|

Density |

Melting Point |

modulus of elasticity |

Thermal conductivity |

|

2.65 Kg/m³ |

591-638 °C |

70.3GPa |

117W/m.K |

annealing state

|

Brand |

annealing state |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of application

|

AluminumUSES AND APPLICATION AREA |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

ElectronicEquipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate |

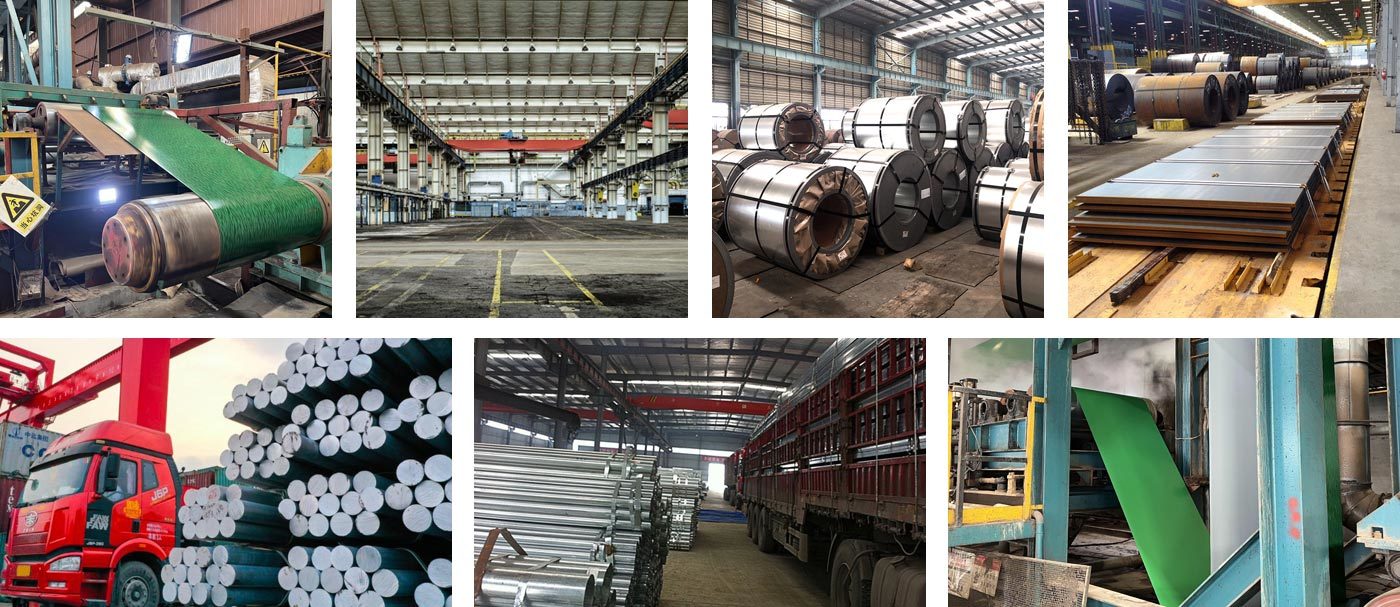

Factory Appearance

Our company is the first wide and thick steel plate production and scientific research base in China. Our company was founded in 1970 and is my country's first wide and thick plate production and scientific research base. We have now become the main base for localization and import substitution of wide and thick steel plates in my country.

Packing and shipping

It possesses two wide and heavy steel plate production lines including one 4100mm line and one 4200mm line of high specialization, with international first class technological equipment and the comprehensive capacity of annually producing over 5 million tons of molten steel and 3 million tons of steel plate. The total assets are 13.2 billion yuan. The number of employees amounts to more than 10,000. The company covers an area of 7.35 m2. The total area of industrial building at plant site is 4.4 million m2. The steel plate heat treatment technology, extra heavy steel plate production technology and ESR steel production technology are all in the leading position of the same industry.

Customer visit

It has 12 product series including low-alloy high-strength steel plates and alloy structural steel plates, more than 300 steel types, and more than 400 thickness specifications of wide and thick steel plate products. It adopts foreign standards to produce more than 180 varieties. The products are exported to more than 100 countries and regions around the world, including Europe, America, and Asia, and are well received by customers at home and abroad.

Application areas

Products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields. It has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system. Positioned to produce and develop high-end wide and thick plates, we continue to innovate and seek transformation, and are willing to provide other hot-rolled plates, medium-thick plates, wire rods, cold-rolled plates, galvanized plates, stainless steel and other steel products to global customers.

RELATED PRODUCTS

GET A FREE QUOTE