Galvanized Corrugated Roof Sheet

Classification :

Galvanized Steel Sheet

Key words:

PRODUCT DETAILS

Galvanized Corrugated Roof Sheet Description

Galvanized roof shingles are made of galvanized steel sheet used for roofing and coated with zinc. The zinc coating provides moisture and oxygen protection for the base steel. According to the galvanizing process, it can be divided into hot-dip galvanized steel plate and electro-galvanized steel plate. The corrugated design will improve its strength and enable it to withstand harsh weather conditions. Common designs include wavy, trapezoidal designs, ribbed galvanized roof panels, etc. It can be used as a single-layer board, covering an existing roof, or a steel sandwich panel.

Galvanized sheet itself is more cost-effective than traditional roofing materials. In addition, it is light in weight and easy and quick to install. In addition, it is durable and recyclable and requires less maintenance. All these factors make galvanized roof panels an economical choice. Galvanized steel roof panels have a bright and smooth surface. The corrugated design is also excellent from the outside. In addition, it has good adhesion, so you can paint it in different colors. Having a galvanized steel roof makes it easy to achieve aesthetic purposes.

Scope of Application

Galvanized corrugated roof panels have good corrosion resistance and long service life. Therefore, it is widely used in industry, commerce, residence and agriculture. Its wide application includes temporary houses, garages, greenhouses, warehouses, barns, stables, sheds, factories, commercial buildings, etc.

Product Parameters

|

Product Name |

Galvanized Corrugated Roof Sheet |

|

Thickness |

0.12mm-6.00mm |

|

Width |

600mm-1500mm |

|

Length |

1m-12m, Support Customization |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

|

Zinc Layer |

Hot Galvanizing: 60-275g/m² |

|

Pre-galvanized: 80-275g/m² |

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

Forcold Forming Chinese Standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

Forcold Forming Japanese Standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For Structure Japanese Standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For Structure AISI Standard |

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Use of The Environment |

Recommended Zinc Thickness |

|

Indoor Use |

Z10 or Z12 (100g/㎡or 120g/㎡) |

|

Suburbs |

Z20 and Painting (200g/㎡) |

|

Urban or Industrial Area |

Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Coastal Area |

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Punch or Deep Drawing Application |

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

|

Surface Treatment Type |

Code |

Features |

|

Chromic Acid Treatment |

C |

Good corrosion resistance, suitable for bare state |

|

Chromic Acid Treatment+Oiling |

S |

Good corrosion resistance |

|

Phosphoric Acid Treatment (Including Sealing Treatment) |

P |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling |

Q |

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment) |

T |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling |

V |

Has a certain corrosion resistance, good paint performance, and prevent rust |

|

Oiling |

O |

Prevent rust during transportation and storage |

|

No Treatment |

M |

Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard |

European Standard |

|

DX51D Z/DC51D Z (CR) |

SGCC |

DX51D Z |

|

DX52D Z/DC52D Z |

SGCD1 |

DX52D With |

|

DX53D Z/DC53D Z/DX54D Z/DC54D Z |

SGCD2/SGCD3 |

DX53D Z/DX54D Z |

|

S220/250/280/320/350/550GD Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD Z |

|

DX51D Z/DD51D Z (HR) |

SGHC |

DX51D Z |

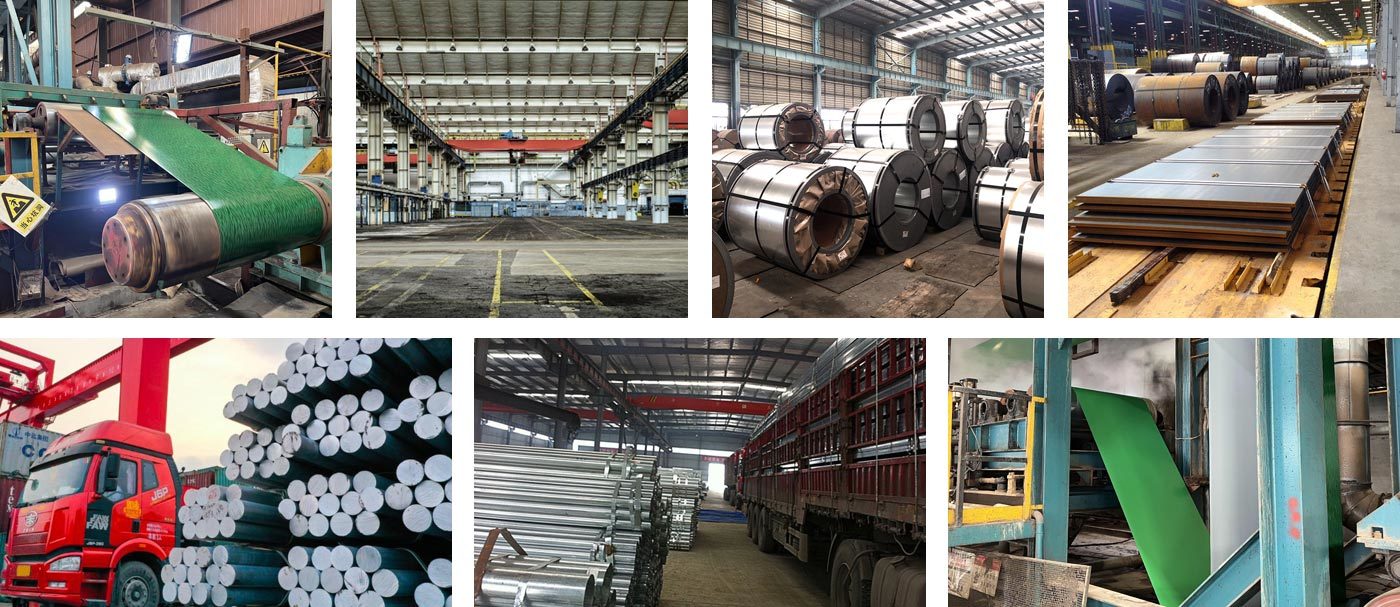

Factory Appearance

Our company is the first wide and thick steel plate production and scientific research base in China. Our company was founded in 1970 and is my country's first wide and thick plate production and scientific research base. We have now become the main base for localization and import substitution of wide and thick steel plates in my country.

Packing and shipping

It possesses two wide and heavy steel plate production lines including one 4100mm line and one 4200mm line of high specialization, with international first class technological equipment and the comprehensive capacity of annually producing over 5 million tons of molten steel and 3 million tons of steel plate. The total assets are 13.2 billion yuan. The number of employees amounts to more than 10,000. The company covers an area of 7.35 m2. The total area of industrial building at plant site is 4.4 million m2. The steel plate heat treatment technology, extra heavy steel plate production technology and ESR steel production technology are all in the leading position of the same industry.

Customer visit

It has 12 product series including low-alloy high-strength steel plates and alloy structural steel plates, more than 300 steel types, and more than 400 thickness specifications of wide and thick steel plate products. It adopts foreign standards to produce more than 180 varieties. The products are exported to more than 100 countries and regions around the world, including Europe, America, and Asia, and are well received by customers at home and abroad.

Application areas

Products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields. It has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system. Positioned to produce and develop high-end wide and thick plates, we continue to innovate and seek transformation, and are willing to provide other hot-rolled plates, medium-thick plates, wire rods, cold-rolled plates, galvanized plates, stainless steel and other steel products to global customers.

RELATED PRODUCTS

GET A FREE QUOTE